How to design parts for Injection Molding

SHARE THIS ARTICLE

SHARE THIS ARTICLE

In this guide you’ll find everything you need to know about injection molding. Master the technology’s basic principles and learn actionable design tips fast that will save you time and cut costs.

Short on time? Download for free the PDF version of the injection molding manufacturing and design guide. In this 40-page e-book, learn everything you need to know about injection molding - from the very basics to advanced design tips.

Download the PDFWhat is a injection molding? How does it work and what is it used for?

Begin part 1Already familiar with the basics? Learn actionable design tips here.

Begin part 2Learn more about the materials and standard finishes used in injection molding.

Begin part 3Use these 3 design tips to keep the cost of injection molding to a minimum.

Begin part 4A step-by-step guide on how to prepare for your first injection molding order.

Begin part 5A list of useful resources if you want to delve deeper.

Begin part 6What is a injection molding? How does it work and what is it used for?

In this section, we answer these questions and show you common examples of injection molded parts to help you familiarize yourself with the basic mechanics and applications of the technology.

Injection molding is a manufacturing technology for the mass-production of identical plastic parts with good tolerances. In Injection Molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. The materials used in Injection Molding are thermoplastic polymers that can be colored or filled with other additives.

Almost every plastic part around you was manufactured using injection molding: from car parts, to electronic enclosures, and to kitchen appliances.

Injection molding is so popular, because of the dramatically low cost per unit when manufacturing high volumes. Injection molding offers high repeatability and good design flexibility. The main restrictions on Injection Molding usually come down to economics, as high initial investment for the mold is required. Also, the turn-around time from design to production is slow (at least 4 weeks).

Injection molding is widely used today for both consumer products and engineering applications. Almost every plastic item around you was manufactured using injection molding. This is because the technology can produce identical parts at very high volumes (typically, 1,000 to 100,000+ units) at a very low cost per part (typically, at $1-5 per unit).

But compared to other technologies, the start-up costs of injection molding are relatively high, mainly because custom tooling is needed. A mold can cost anywhere between $3,000 and $100,000+, depending on its complexity, material (aluminum or steel) and accuracy (prototype, pilot-run or full-scale production mold).

All thermoplastic materials can be injection molded. Some types of silicone and other thermoset resins are also compatible with the injection molding process. The most commonly used materials in injection molding are:

Even if we take into account all other possible manufacturing technologies, injection molding with these four materials alone accounts for more than 40% of all plastic parts produced globally every year!

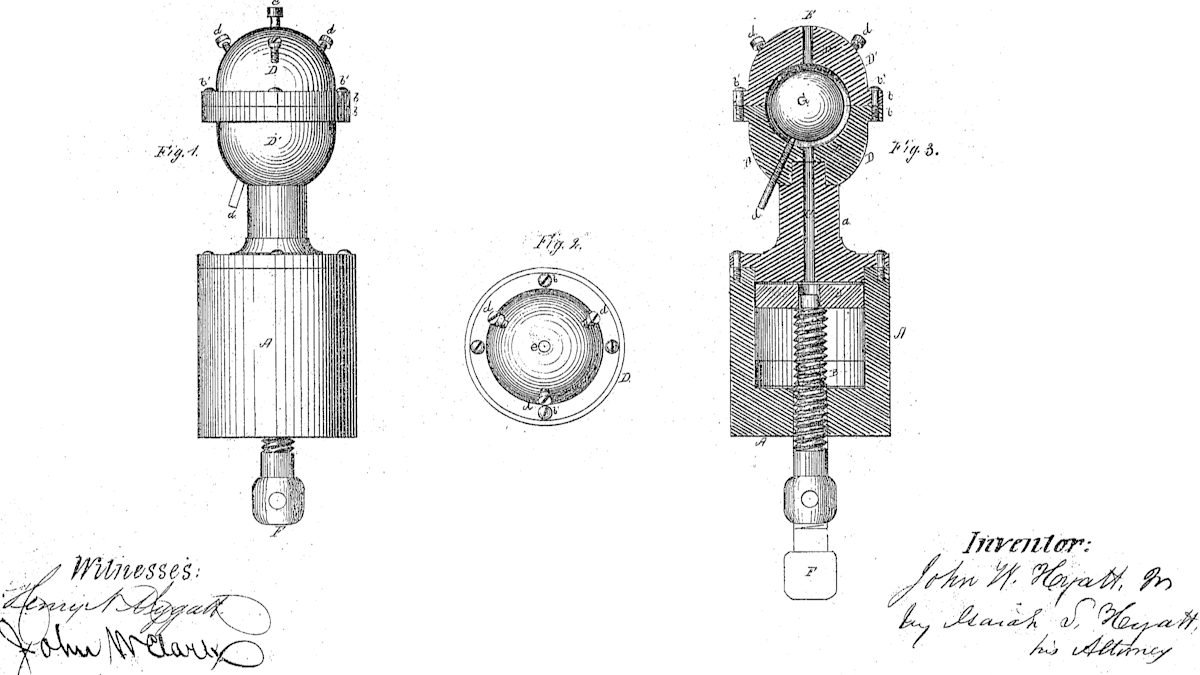

In 1869, John Wesley Hyatt invented celluloid, the first practical artificial plastic intended to replace ivory for the production of… billiard balls! Early injection molding machines used a barrel to heat up the plastic and a plunger to inject it to the mold.

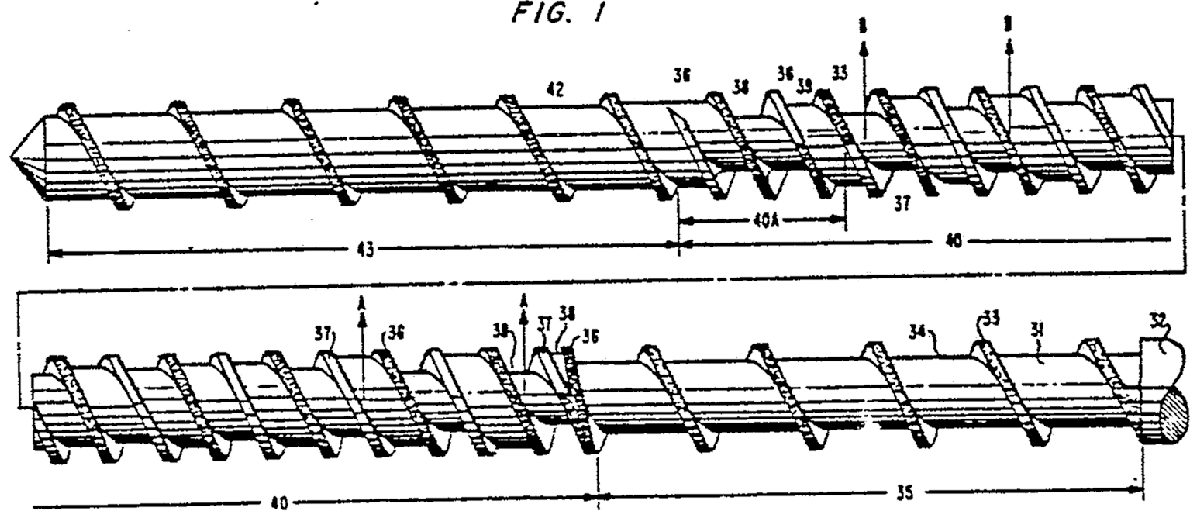

In the mid 1950s, the invention of the reciprocating screw single-handedly revolutionized the plastics industry. The reciprocating screw solved key issues with uneven heating of the plastic that previous systems faced, and opened up new horizons for the mass production of plastic parts.

Today, injection molding is a $300 billion market. 5+ million metric tons of plastic parts are produced with injection molding globally each year. Recently, the demand of biodegradable materials is increasing for environmental reasons.

An injection molding machine consists of 3 main parts: the injection unit, the mold - the heart of the whole process - and the clamping/ejector unit.

In this section, we examine the purpose of each of these systems and how their basic operation mechanics affect the end-result of the Injection molding process.

Watch a large injection molding machine in action while producing 72 bottle caps every 3 seconds in the video here:

The purpose of the injection unit is to melt the raw plastic and guide it into the mold. It consists of the hopper, the barrel, and the reciprocating screw.

Here is how the injection molding process works:

The whole process can be repeated very fast: the cycle takes approximately 30 to 90 seconds depending on the size of the part.

The mold is like the negative of a photograph: its geometry and surface texture is directly transferred onto the injection molded part.

It usually makes up the largest portion of the start-up costs in injection molding: the cost of a typical mold starts at approximately $2,000-5,000 for a simple geometry and relatively small production runs (1,000 to 10,000 units) and can go upwards to $100,000 for molds optimized for full-scale production (100,000 units or more).

This is due to the high level of expertise required to design and manufacture a high-quality mold that can produce accurately thousands (or hundreds of thousands) of parts.

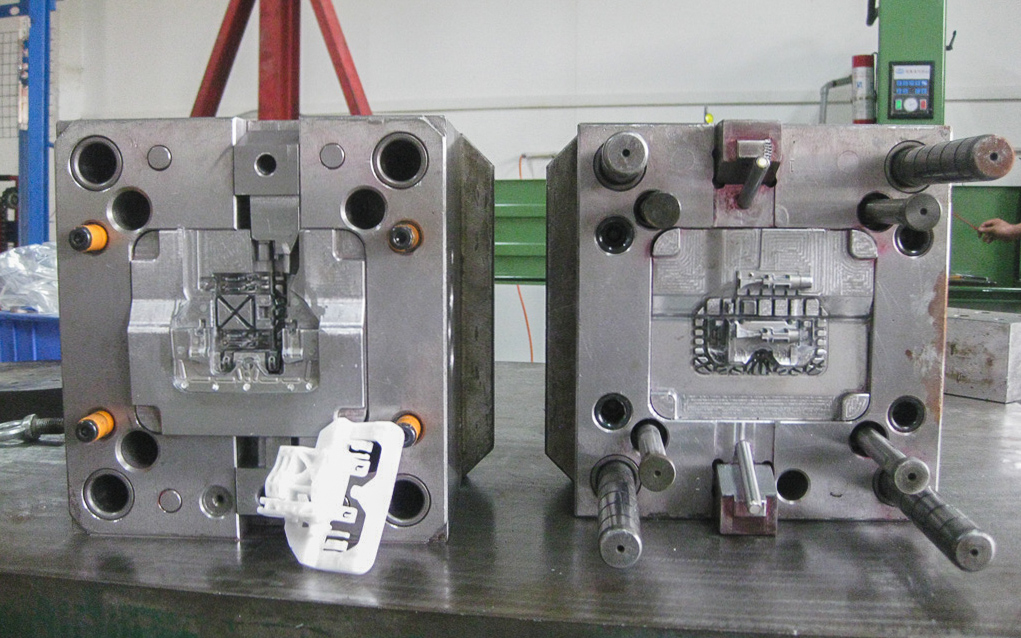

Molds are usually CNC machined out of aluminum or tool steel and then finished to the required standard. Apart from the negative of the part, they also have other features, like the runner system that facilitates the flow of the material into the mold, and internal water cooling channels that aid and speed up the cooling of the part.

Recent advances in 3D printing materials have enabled the manufacturing of molds suitable for low-run injection molding (100 parts or less) at a fraction of the cost. Such small volumes were economically unviable in the past, due to the very high cost of traditional mold making.

*An industrial mold design for producing a tens of thousands of parts number of plastic parts. The cavity is show on the left and the core on the right.*

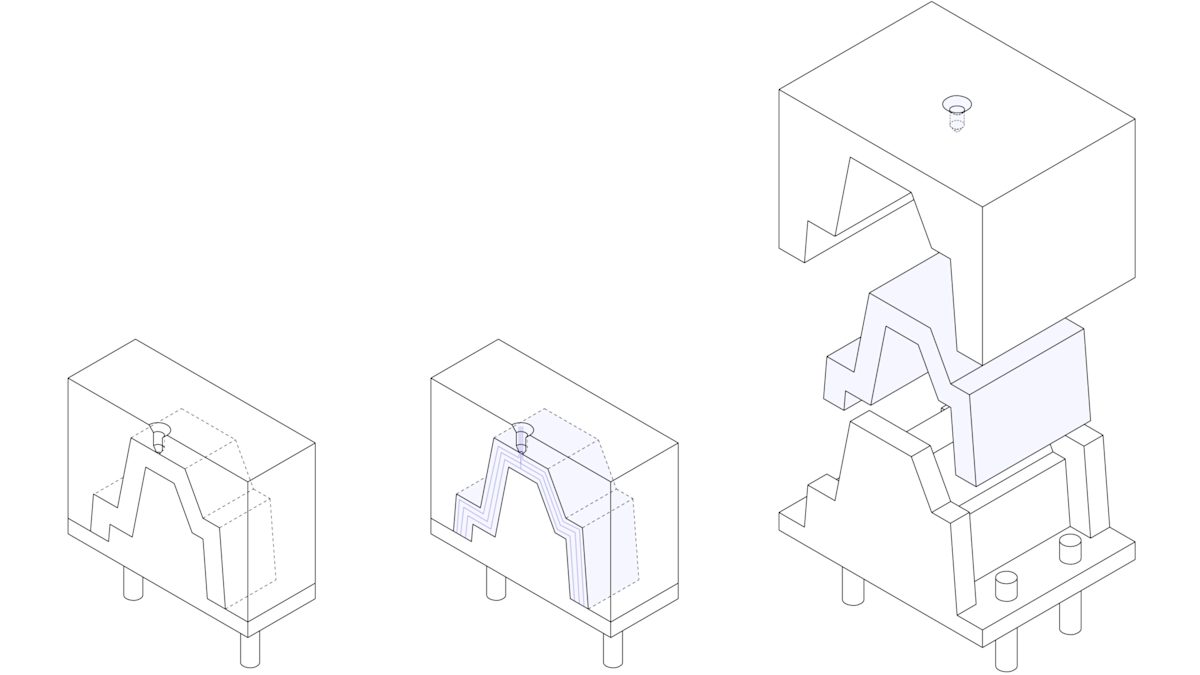

The simplest mold is the straight-pull mold. It consist of 2 halves: the cavity (the front side) and the core (the back side).

In most cases, straight-pull molds are preferred, as they are simple to design and manufacture, keeping the total cost relatively low. There are some design restrictions though: the part must have a 2.D geometry on each side and no overhangs (i.e. areas that are not supported from below).

If more complex geometries are required, then retractable side-action cores or other inserts are required.

Side-action cores are moving elements that enter the mold from the top or the bottom and are used to manufacture parts with overhangs (for example, a cavity or a hole). Side-actions should be used sparingly though, as the cost increases rapidly.

Interesting fact: About 50% of the typical injection molding cycle is dedicated to cooling and solidification. Minimizing the thickness of a design is key to speed up this step and cuts costs.

Injection molded parts have two sides: the A side, which faces the cavity (front half of the mold) and the B side, which faces the core (back half of the mold). These two sides usually serve different purposes:

The runner system is the channel that guides the melted plastic into the cavity of the mold. It controls the flow and pressure with which the liquid plastic is injected into the cavity and it is removed after ejection (it snaps off). The runner system usually consists of 3 main sections:

Different gates types are suitable for different applications. There are 4 types of gates used in injection molding:

At the point where the runner system connected with the part, a small imperfection is usually visible, called the vestige.

If the presence of the vestige is not desirable for aesthetic purposes, then in can also be “hidden” in the functional B-side of the part.

On the far side of an injection molding machine is the clamping system. The clamping system has a dual purpose: it keeps the 2 parts of the mold tightly shut during injection and it pushes the part out of the mold after it opens.

After the part is ejected, it falls onto a conveyor belt or a bucket for storage and the cycle starts over again.

Alignment of the different moving parts of the mold is never perfect though. This causes the creation of 2 common imperfections that are visible on almost every injection molded part:

The image below shows the mold used to manufacture both sides of the casing for a remote controller. Quick quiz: try to locate the *core* (A-side), the *cavity* (B-side), the runner system, the ejector pins, the side-action core and the air vents on this mold.

Injection molding is an established manufacturing technology with a long history, but it’s constantly being refined and improved with new technological advancements.

Below is a quick rundown of the key advantages and disadvantages of injection molding to help you understand whether it’s the right solution for your application.

Injection molding is the most cost-competitive technology for manufacturing high volumes of identical plastic parts. Once the mold is created and the machine is set up, additional parts can be manufactured very fast and at a very low cost.

The recommended minimum production volume for injection molding is 500 units. At this point economies of scale start to kick-in and the relatively high initial costs of tooling have a less prominent effect on the unit price.

Wide range of materialsAlmost every thermoplastic material (and some thermosets and silicones) can be injection molded. This gives a very wide range of available materials with diverse physical properties to design with.

Parts produced with injection molding have very good physical properties. Their properties can be tailored by using additives (for example, glass fibres) or by mixing together different pellets (for instance, PC/ABS blends) to achieve the desired level of strength, stiffness or impact resistance.

Very high productivityThe typical injection molding cycle lasts 15 to 60 seconds, depending on the size of the part and the complexity of the mold. In comparison, CNC machining or 3D printing might require minutes to hours in order to produce the same geometry. Also, a single mold can accomodate multiple parts, further increasing the production capabillities of this manufacturing process.

This means that hundreds (or even thousands) of identical parts can be produced every single hour.

Great repeatability and tolerancesThe injection molding process is highly repeatable and the produced parts are essentially identical. Of course, some wear occurs to the mold over time, but a typical pilot-run aluminum mold will last 5,000 to 10,000 cycles, while full-scale production molds from tool steel can stand 100,000+ cycles.

Typically, injection molding will produce parts with tolerances of ± 0.500 mm (0.020’’). Tighter tolerances down to ± 0.125 mm (0.005’’) are also feasible in certain circumstances. This level of accuracy is enough for most applications and comparable to both CNC machining and 3D printing.

Excellent visual appearanceA key strength of injection molding is it can produce finished products that need little to no extra finishing. The surfaces of the mold can be polished to a very high degree to create mirror-like parts. Or they can be bead blasted to create textured surfaces. The SPI standards dictate the level of finishing that can be achieved.